Description

PFG-03C is designed for the production of full-colour reflection holograms using CW or multi-pulsed laser radiation. For plate sizes starting from 500 × 600 mm glass thickness is 3mm. Guaranteed material lifetime – 6 months, so they are manufactured on request.

GEO-03 is a special version of PFG-03C which was developed under Geola’s guidance to record holograms with pulsed laser. It has peak sensitivities at 440nm, 532nm and 660nm. In conjunction with Geola RGB lasers one can obtain bright colour holograms on this photomaterial and not be afraid of vibration. Those plate are available under special order – minimum order value 10,000 Eur.

Characteristics

PFG-03C

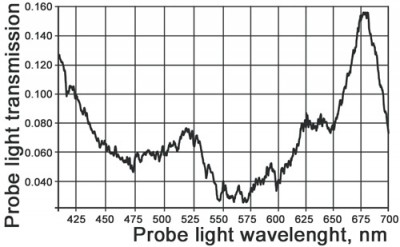

A spectral sensitivity curve of the PFG-03C is shown in Fig. 2. Diffraction efficiency versus exposure is shown in Fig. 3. The maximum diffraction efficiency in the blue region is >25% and in the green and red regions >45%.

Typical sensitivity values for PFG-03C are 2mJ/cm2 and 3mJ/ cm2 for the blue and red/green regions respectively. The grain size distribution curve for both PFG-03C and GEO-3 is shown on Fig. 1. Diffraction efficiency – on Fig. 3.

Recommended processing is given at the end of the article.

GEO-03

Absorption spectrum of GEO-03 is shown in Fig.4. The sensitivity and diffraction efficiency of this material are given in the table below.

| GEO-03 sensitivity and diffraction efficiency for diffused mirrors holograms recorded with pulsed and CW radiation | Measured values |

| Exposure, microJ/cm2 (calculate your own) | |

| @ 457nm, CW, microJ/cm2 | 1250±200 |

| @ 440nm, ~30ns pulse, microJ/cm2 | 120±20 |

| @ 514.5nm, CW, microJ/cm2 | 1800±200 |

| @ 532nm, ~30ns pulse, microJ/cm2 | 330±30 |

| @ 633nm, CW, microJ/cm2 | 1900±250 |

| @ 660nm, ~30ns pulse, microJ/cm2 | 550±50 |

| Diffraction efficiency for reflection holograms (diffused mirrors), % | |

| @ 457nm, CW | 27.0±3 |

| @ 440nm, ~30ns pulse | 14.0±2 |

| @ 514.5nm, CW | 35.8±3 |

| @ 532nm, ~30ns pulse | 16.5±2 |

| @ 660nm, ~30ns pulse | 14.2±2 |

| @ 633nm, CW | 38.3±3 |

Processing and Handling Recommendations

- Unseal and process in indirect dark green non-actinic light.

- Temperature of processing solutions – 20°C.

- Storage condition: Humidity 45% and 4 deg. Celsius.

Table below shows recommended processing scheme for use with PFG-03C and GEO-03 after CW, multi-pulse or pulsed exposure.

| Procedure | PFG-03, CW exposure | GEO-03, CW exposure | GEO-03, pulsed exposure |

| Exposure: (calculate your own) | 1.5 – 2.0 mJ/cm2 | 120-550microJ/cm2 | |

| Development/Hardening | SM-6 + Formaldehyde 37% (10 ml to 1 liter of developer), 2-5min – until unexposed areas will darken to 1,5-2 density | ||

| Wash | Water, 2min | ||

| Bleach | PBU-Amidol 5 min: ~ 2 min until expesed areas became clear (if exposure dose and developing time were right) plus 3 min. | ||

| Wash | Water 5 min. | ||

| Drying in Alcohol bath | 50% Isoprophyl alcohol 4min | ||

| Drying | Slow Air | ||

Download processing instructions from here.

Storage

The developer solution without Formaldehyde remains developing properties while stored for three days. Add formaldehyde half an hour before processing.

Bleaching solution can be stored for about one week.

Processing even one plate in the developing and bleaching solutions noticeably reduce their lifetime to 24-48 hours.

All solutions should be stored in the closed dark glass or non-active dark plastic bottles. You can store them in a room temperature, but it is better to store them in the refrigerator at +5 degrees Celsius.

Work with chemicals

It is important to follow good laboratory practice while processing the photomaterials. The chemicals included in Geola’s set are not poisonous, however, please wipe up any spillage as soon as it occurs and use the polythene gloves. Download safety instructions here.