Description

Geola’s Originators print master-original holograms for embossed holography applications – for the manufacture of either high security holograms or decorative holograms for brand protection.

Geola’s uniquely designed pulsed laser technology drives most of our Originators. Holograms can be printed simultaneously on a standard originating area, thus obviating further mechanical hologram recombination.

The state-of-the-art Originators Series currently consists of three machines types:

- IMP-6 – Image-Matrix Printer – the working principle of those Originators is similar to Kinemax or Firefly, but the machine itself is easier to operate, is cost-effective and (we are sure) produces better holograms. Those originators employ either a CW or a pulsed laser. The pulsed laser option allows the printing of large format master-originals much quicker than with any other originator.

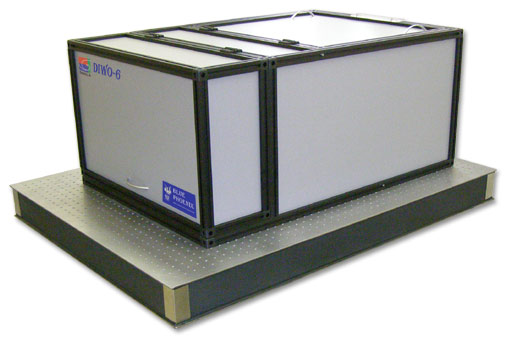

- DIWO-6 – Direct Write Originators – the working principle is similar to that of our printers for poster-sized holograms. This originator uses a pulsed laser to rapidly record deep holographic 3D images, with an image depth of up to 75% of the hologram width, onto a photoresist plate. The CW laser also can be employed in this originator, but the printing process will happen much slower.

- IMP-6-DW – this machine combines IMP and DIWO originators writing heads allowing the origination of master-holograms containing deep 3D holographic images and all modern optical security features.

Standard origination area for holograms is 150x150mm (6″x6″) and can be enlarged on demand. Positive photoresist plates are required for printing. Geola can supply positive photoresist plates 200x250mm or 200x300mm.

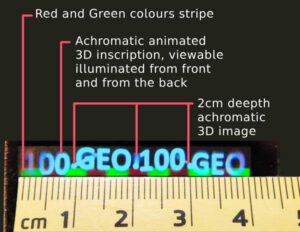

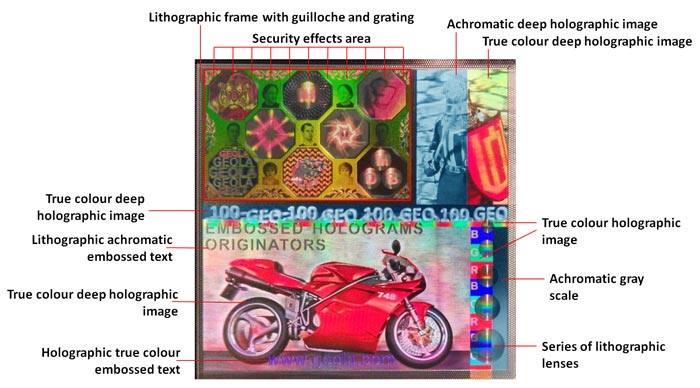

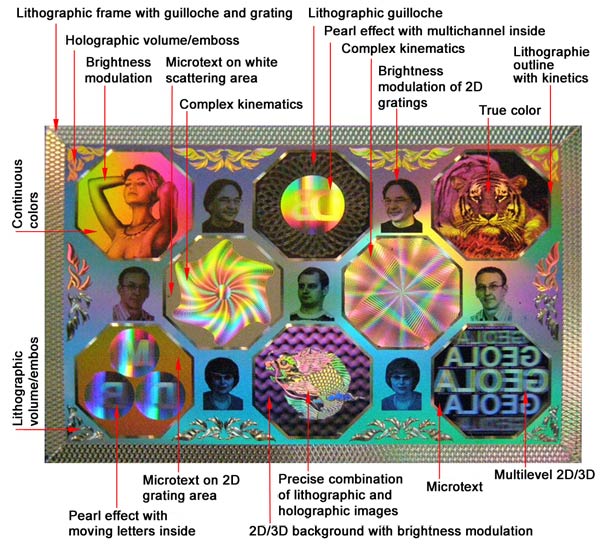

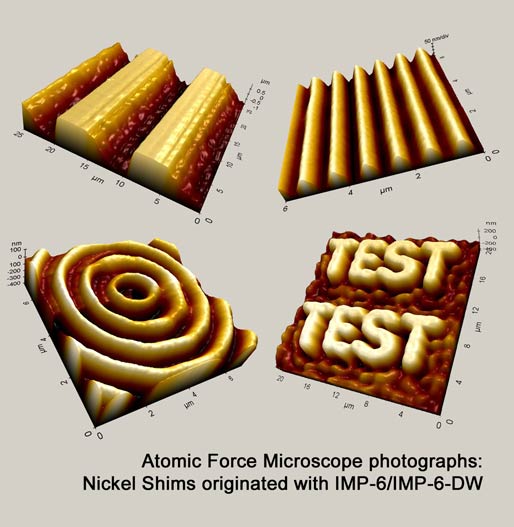

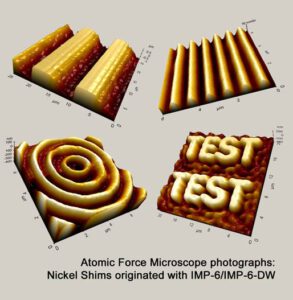

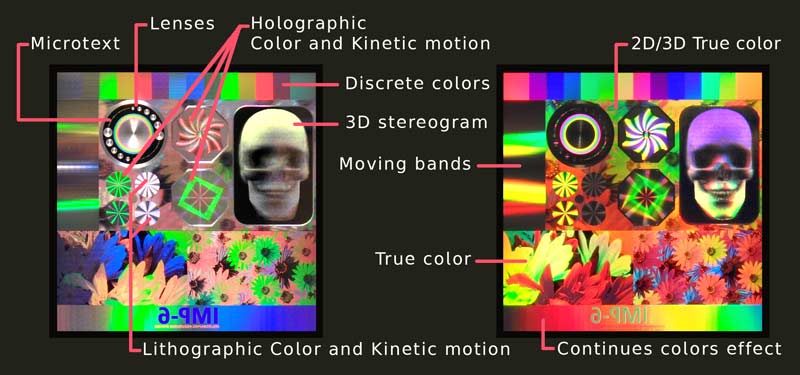

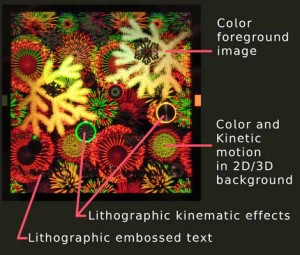

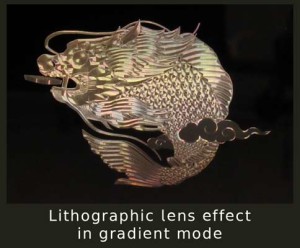

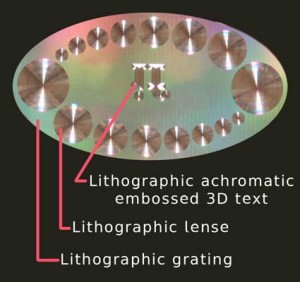

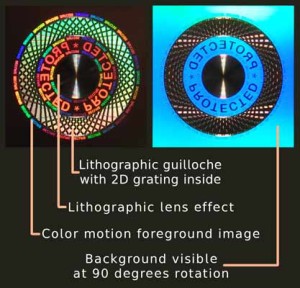

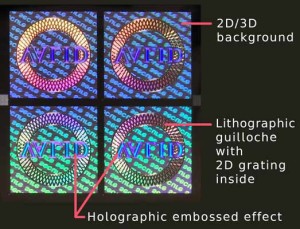

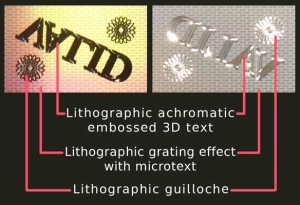

Photographs of some effects produced with our Originators

Security features on this hologram are suitable for banknotes and ID windows. This hologram is possible to produce only with our Originators.

Invited presentations about our Originators were given at the conferences:

- The Holography Conference 2017

- High Security Printing Asia 2017

- High Security Printing EMEA 2018

- SPIE Photonics West 2018 – download the article and PowerPoint presentation.

Download our Originators Powerpoint presentation at HSP EMEA 2018

IMP-6 – Image-Matrix Printer

The Blue Phoenix IMP-6 Originators allow the origination of all commonly used types of security holograms and diffractive optical elements. The Originators have three operating modes – holographic, lithographic and combined mode with fully programmable switching between these modes during hologram origination.

The Blue Phoenix IMP-6 Originators allow the origination of all commonly used types of security holograms and diffractive optical elements. The Originators have three operating modes – holographic, lithographic and combined mode with fully programmable switching between these modes during hologram origination.

The originating area of standard holograms is 150x150mm (6″x6″) and can be enlarged on demand. If IMP-6 originators are equipped with a pulsed laser, this area can be filled with identical or different holograms in only several hours, thus making mechanical recombination unnecessary.

Positive photoresist plates are used as the printing medium. Origination is accomplished by the exposition of a desired photoresist area, filling it with holographic micro-frames, each of which contains elementary holograms and subsequently developing the obtained diffractive structure in an etching solution.

Invited presentations about our Originators were given at the conferences:

- The Holography Conference 2017

- High Security Printing Asia 2017

- High Security Printing EMEA 2018

- SPIE Photonics West 2018 – download the article and PowerPoint presentation.

Download our Originators Powerpoint presentation at HSP EMEA 2018

Security hologram samples

Please visit IMP-6 security holograms and diffractive optical elements page for IMP-6 sample works.

Features

HARDWARE

- Holographic micro-frame size – 225x126micrometers

- Size of the Elementary hologram in micro-frame – from 1x1micrometers

- Elementary holograms density – up to 26,000 elementary holographic pixels per inch)

- Graphic resolution up to 210,000dpi

Originating area

200x200mm

(Bigger areas available on request)

Modulator type

LCOS 1920x1080pixels

Laser

High performance 405nm laser or Geola’s BlueBird series pulsed laser

Focussing

With CCD camera

SOFTWARE

Included programs

- Layers creation programs (effects generation and calculation programs)

- Visualizer

- Hologram recording program.

The hologram is built by a combination of layers containing different visual effects. The number of layers is not limited. It is possible to have any combination of holographic and lithographic layers in the design of one hologram. Final and (any) intermediate results can be visualized by our software and verified during design work. The software for hologram layer creation is not interfaced with the software for hologram recording and can be installed on any number of computers for designers’ convenience.

In the case of availability of new Originator software, all upgrades will be free of charge for one year after installation.

In the case of new Originator’s software availability, all upgrades will be free of charge for one year after the installation.

OPERATION

| Originating modes | Holographic mode |

| Lithographic mode | |

| Combined Holographic-Lithographic mode | |

| Switch between holographic and lithographic operation modes is performed on the fly automatically in 0.5sec. with absolute positioning accuracy. | |

| Originating speed | ~ 1 sq.cm per 30 minutes with CW laser |

| ~ 1 sq.cm per 7 minutes with pulsed 30Hz laser | |

| ~ 1 sq.cm per 3 minutes with pulsed 60Hz laser | |

| Grating pitch | Holographic mode: variable 700–1400lines/mm |

| Lithographic mode: variable 1–500lines/mm | |

| Number of colors | Rainbow colors: 430-680nm range with 1nm resolution |

| Mixed colors: holographic white and magenta | |

| Number of direction | Holographic mode: 0-180degrees |

| Lithographic mode: 0-360degrees | |

| With 1 degree design resolution and 0.1degree recording resolution | |

| Focussing modes | Whole area focusing |

| Local focusing | |

| Autofocusing | |

ENVIRONMENT

- Originator’s operating room size – not less than 2x2x2meters

- Operating voltage – 230V

- Power consumption < 100 W

- Operating temperature – 21±2 degrees Celsius

- Operating humidity – 50±10%

- Exposed plates processing room – not less than 1×1.5×2 meters, with fume extraction.

DIWO-6 – Direct Write Originators

The Blue Phoenix DIWO-6 Originatorsquickly and easily imprints deep 3D holographic images of live or virtual objects onto a photoresist surface. Those are the only Originators on the market employing pulse laser for photoresist exposure. As a result, they are the quickest Originators ever.

From all the commonly used security features those Originators produces only hidden images, but necessary optical security features can be overprinted by an IMP-6 or any other originator on top of the undeveloped photoresist plate exposed by the DIWO-6.

The machine produces master-original holograms on positive type photoresist plates. Origination is done by exposing a desired photoresist area, covering it with holographic micro-frames each of which contains elementary holograms and subsequently developing the obtained diffractive structure in an etching solution.

Invited presentations about our Originators were given at the following conferences: The Holography, HSP Asia, HSP EMEA and SPIE Photonics West 2018 – download the article and PowerPoint presentation.

Features

The only originators in the world quickly producing deep holographic 3D images on photoresist medium.

| Unique features | Direct Write of true colour deep 3D transmission holograms with pulsed laser |

| Direct Write of achromatic deep 3D holograms viewable in front and back illumination with pulsed laser | |

| Holographic frames are the smallest on the market – only 100x100micrometers | |

| Pulsed laser makes this Originator the quickest on the market | |

| Originated hologram of 3D object contains from 200 to 800 its perspective views | |

| Graphical and security effects | True holographic 3D images |

| Minimal imprinted text size – 0.7mm | |

| Hidden images (CLR) static and animated | |

| Holographic Diffractive elements | Color motion and kinetic motion |

| True color 2D, True colour 2D/3D | |

| True color stereograms with 200-800 parallax views | |

| Multilayer 2D/3D with unlimited number of layers |

Hardware

• Holographic micro-frame size – 100x100micrometers

• Each holographic micro-frame contains 200-800 2D image pixelsOriginating area

152x152mm (6″x6″)

(Bigger areas available on request)Originating speed

~ 1 sq.cm per 7 minutes with pulsed 30Hz laser

~ 1 sq.cm per 3 minutes with pulsed 60Hz laserModulator type

LCOS

Laser

Geola’s BlueBird series pulsed laser, 440nm, repetition rate – from 60Hz to 120HzFocussing

With CCD camera, autofocusing per four defining points

Software

Included programs

• Holoprocessor

• Visualizer

• Hologram recording program

Information for digital 3D hologram is obtained from digital pictures pixels. Our software from series parallax-relates images takes pixels with same coordinates and combines from them holographic micro-frames called also holopixels or hogels. Each of such micro-frames contains 200-800 2D pixels replaying into 200-800 viewing angles. The program to create holopixel images for whole hologram is independent from hologram recording program and can be installed on any number of computers for designers convenience. Hologram visualizing program creates hologram preview from series of parallax-related images and also can be installed on all designers computers.

Environment

Originator’s operating room size – not less than 3x2x2meters

Operating voltage – 230V

Power consumption < 500 W

Operating temperature – 21±2 degrees Celsius

Operating humidity – 50±10%

Exposed plates processing room – not less than 1×1.5×2 meters, with fume extraction.