Holography

Holography it is the method to record and replay a three-dimensional image of three- dimensional object in the form of hologram. Roughly speaking – it is the method to record all the information about three-dimensional object shape in a special media. When such a media is illuminated by the point light source (halogen lamp or sun), this information is replayed and the three-dimensional object appears hung in the air in front and inside the media. When observer is changing his position, it is possible to see all the details of the three-dimensional scene, like in a real life.

Photomaterials for holography

PFG-01 or PFG03M- if you have red laser light (for example, HeNe laser);

VRP-M- if you have green or blue laser light;

PFG-03C- if you have the RGB (red, green, and blue) lasers

The emulsion itself is totally the same- the only difference is that VRP plates have antihalation coating, while VRP-M plates don’t.

We do try to get the lowest possible costs of shipping.

Mainly, the cost of shipping depends on the size/weight of your ordered goods – get in touch with us and ask.

Yes, we do accept orders for custom sizes. Please, get in touch with us and ask.

Film-triacetate substrate, thickness 180mkm, refraction index 1.6

Plates- glass, thickness 2.6mm (varies from 2 to 2.6mm batch to batch), refraction index 1.6

The photoemulsion has also the same refraction index – 1.6

(This applies for the VRP-M, PFG-01, PFG-03C and PFG-03M, refraction index for the PFG-04 plates is unknown)

Please, download instructions here.

You can keep opened sm6 set in dry room up to 2 years;

Lifetime of mixed SM-6 developer solution in 22 degrees of Celsius room temperature is about 2.5 days (for PBU-Amidol bleach lifetime is the same). To decries solutions degradation they should be kept in low temperature (up to 15C) and oxygen isolated (For example: in plastic bottle with screw cap ).

For powder chemicals: organic (like Phenidone ) chemicals lifetime is about 2 years, for not organic – in dry cold (up to 15C temperature) – is not limited.

In one liter of ready developer there is possible to process up to 100 sheets of the PFG-01 (or VRP-M) film (sheet’s dimensions 102x127mm). If you are expecting to process less film in one session, please reduce the quantity of the chemicals accordingly. Totally there will be enough ready developer and bleach to develop ~1 square meter of materials.

Yes. SM-6 developer and PBU-Amidol can be succesfully applied for PFG-01, VRP-M, PFG-03C and PFG-03M emulsions.

Distilled or demineralised (deionized) water.

Geola’s digitaly produced holograms – i-Lumograms

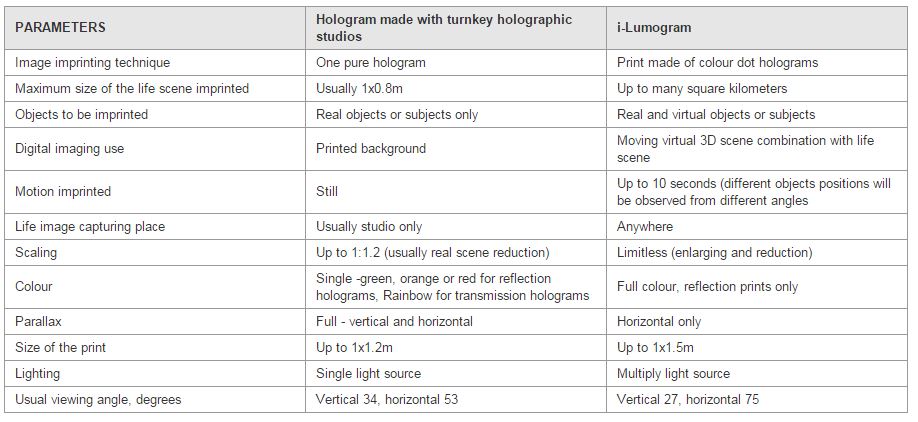

The closest image imprinting technique to our i-Lumogram is the hologram. And like the hologram our i-Lumogram contains all the information about the three-dimensional shape of the imprinted object, just like a small sign with a bird on your Visa Card. In addition, our print contains the information about the three-dimensional object movements. But our holographic prints are bigger and printed in a completely different way than conventional Visa Card type holograms are.

It is true-colour, high resolution and poster sized four-dimensional prints, exposed with Geola’s pulsed RGB lasers on a special photofilm, which is then chemically processed and dried. The key point of this printing method is the dot exposure of said photofilm, performed by six RGB laser light beams, hitting the photofilm from the opposite direction. Three of those beams (one for each RGB colour) contain the part of the information about four-dimensional object shape and another three beams works as the reference beam. When the beams meet, they interfere with each other and the information contained in one of them is stored in the photofilm. In such a way a lot of micro-holograms are recorded on the photofilm and each of them contains the part of the information about the four-dimensional shape of the objects printed. After this dot-exposure, the photofilm is chemically processed, dried and laminated on the high-quality black plastic.

Our i-Lumograms usually have single parallax – which means that you will see the side-to-side changes in time of three-dimensional shape only. But not top-to-bottom shape changes. It is a big advantage of our i-Lumograms – they bring the same message for the people of the different height.

Yes, skilled 3D designers can do the virtual scene’s modeling from the usual photographs, but of course such model will not contain all the details of the real scene that were visible when the photograph was shot. Usual photography contains only 2 dimensions (photo images doesn’t contain depth), so better i-Lumograms can be made from the sequence of a real scene views made by shooting the scene with the Geola’s imaging equipment or by modeling the scene with 3D modeling software like 3D StudioMax.

Museum artifacts, advertising, cartography, portraiture, decoration, celebrities, architecture, medicine, education, gifts and many other applications where the three-dimensional shape of the objects needs to be presented.

That would be difficult. The three-dimensional objects on our i-Lumogram become visible when illuminated from the front side by the point light source, which light hits the print at ~40 degrees angle. While doing that outdoors, you would need to compete with the sunlight. However if you would like to do that at twilight or nighttime – it would be possible if you will assure the security of the said light source.

Our i-Lumograms are done on special photofilm that contains same components as convenient colour photo paper. So the lifetime of i-Lumogram is pretty same as the lifetime of colour photographs and depends on the exposing conditions. Direct sunlight destroys our i-Lumogram in about a year. As for indoor applications – we still have in our laboratory the very first prints from 1999, no image degradation observed.

No degradation observed for the prints not exposed in direct sunlight.

From 18x24cm to 1(vertical) x1.5 (horizontal) meters.

Today it is two square meters per day for i-Lumograms in size from 40x60cm to 1×1.5m, or one square meter per day for i-Lumograms in size from 18×24 to to 40x60cm.

Any kind. Big three-dimensional objects like buildings or mountains should be designed in three-dimensional design program 3D StudioMax. But it is not necessary to create digitally people and other subjects or objects whose size is smaller than 3m(width) x 2,5m(height) x 4m(depth) – those subjects or objects can be digitally photographed with Geola’s HoloCam device.

Yes you can. Geola’s HoloCam produces the same kind of images of a real scene as 3D StudioMax rendering engine does for a virtual scene. The pairs of real and virtual images can be then easily combined with video-post processing program.

Geola’s pulsed RGB laser does the exposure of the photofilm. But, after the chemical processing the hologram is laminated on the black plastic. So, in the matter of fact i-Lumogram has some kind of CMYK colour separation. That’s why the quality of the black plastic on which holograms are laminated is so important.

The image on our prints is formed by a lot of small holograms, so it is not possible to define our i-Lumogram resolution in convenient dots per inch terms. In each small hologram we are imprinting from few hundred to 1200 usual image pixels. The biggest resolution of the images we are using is 1258×1875 pixels. But visually our i-Lumograms corresponds to digital prints with resolution of ~100 dpi.