Description

A heart of Diode-Pumped Solid-State (DPSS) lasers or laser amplifiers are Laser Gain Modules (pump chamber). By evolving laser gain modules, Geola Digital can provide DPSS laser gain modules based on Vertical Cavity Surface Emitting Laser (VCSEL) pumping engine technology. Our DPSS laser gain module engines assures uniform gain distribution, high pumping efficiency and long life time. We have two types of gain modules, namely Water cooled gain modules and Passively cooled gain modules. Typical air cooled DPSS Gain modules can be applicable for Nd:YAG Master Oscillator or Nd:YAG laser amplifier. The customized laser gain modules can be also designed and provided on request.

Main advantages

- Low wavelength shift (0.07 nm/K)

- Wide operation temperature range -20 ℃ — +75 ℃

- High temperature working up to 75℃

- Up to >20G shots life-time

- Stored energy is up to 30% from optical pump energy

- Uniform pumping distribution

- Good power/size form factor

Application

- Gain module for air cooled DPSS master oscillator

- Gain module for air cooled DPSS Nd:YAG laser amplifier

- Gain module for potential military application

Typical Water Cooled Laser Gain Models*

| Gain Model No. | Nd:YAG crystal, mm | SLD chips, pcs | Electrical Pump Power, W | Typical Output Energy, mJ** |

|---|---|---|---|---|

| SLD-3×3-3 | ∅3 | 9 | 1350 | >108 |

| SLD-3×5-3 | ∅3 | 15 | 2250 | >180 |

| SLD-3×7-3 | ∅3 | 21 | 3150 | >252 |

| SLD-3×6-4 | ∅4 | 18 | 2700 | >216 |

| SLD-3×10-4 | ∅4 | 30 | 4500 | >360 |

| SLD-5×7-6 | ∅6 | 35 | 5250 | >420 |

| SLD-5×9-6 | ∅6 | 45 | 6750 | >540 |

| SLD-5×10-6 | ∅6 | 50 | 7500 | >600 |

| SLD-5×15-6 | ∅6 | 75 | 11250 | >900 |

| SLD-5×7-8 | ∅8 | 35 | 5250 | >420 |

| SLD-5×9-8 | ∅8 | 45 | 6750 | >540 |

| SLD-5×13-8 | ∅8 | 65 | 9750 | >780 |

| SLD-7X6-10 | ∅10 | 42 | 6300 | >504 |

| SLD-7×11-10 | ∅10 | 77 | 11550 | >924 |

| SLD-7×15-10 | ∅10 | 105 | 15750 | >1260 |

| SLD-7×10-12 | ∅12 | 70 | 10500 | >840 |

| SLD-7×15-12 | ∅12 | 105 | 15750 | >1260 |

| SLD-9×10-12 | ∅12 | 90 | 13500 | >1080 |

| SLD-9×15-12 | ∅12 | 135 | 20250 | >1620 |

| SLD-9X10-15 | ∅15 | 90 | 13500 | >1080 |

| SLD-10×14-15 | ∅15 | 140 | 21000 | >1680 |

| SLD-10×8-25.4 | ∅25.4 | 80 | 12000 | >960 |

| SLD-10×24-25.4 | ∅25.4 | 240 | 36000 | >2880 |

| SLD-12×20-25.4 | ∅25.4 | 240 | 36000 | >2880 |

| SLD-15×16-25.4 | ∅25.4 | 240 | 36000 | >2880 |

*Specifications marked ‘typical’ are indications of typical performance and will vary with each unit we manufacture

**Data measured at 200us, 20Hz in a 250mm Plano-Plano cavity with T=20% output coupler.

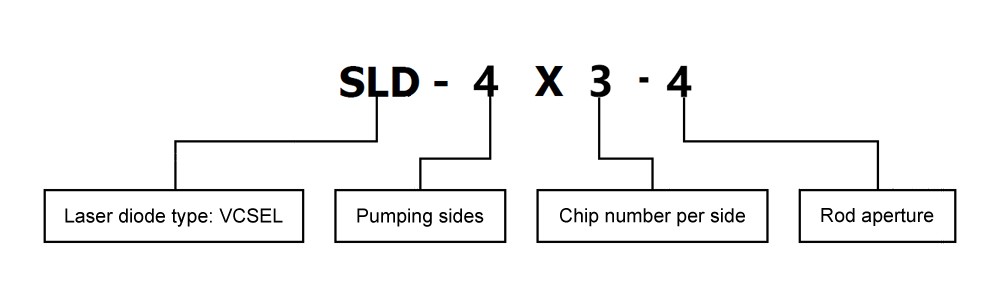

Ordering information

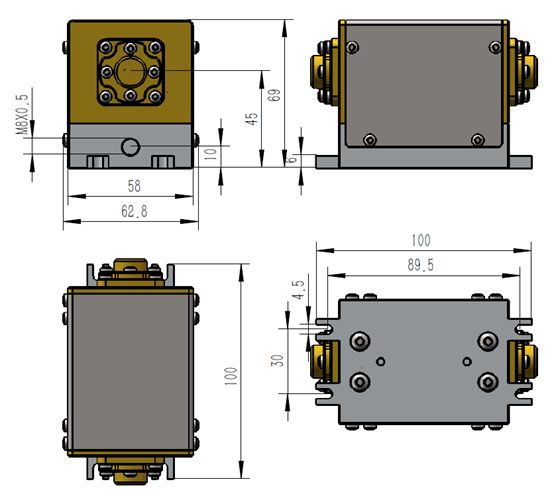

Dimensions***

***One of design example

Module size, pump power, cooling fitting type and location and mechanical parts could be customized.